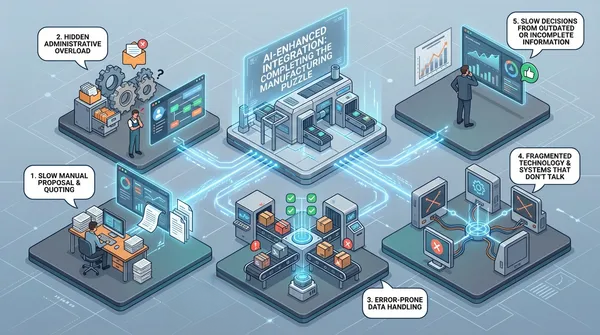

How Small Operational Gaps Quietly Erode Margins and How Modern Manufacturers Are Using AI to Uncover and Eliminate Them

Small manufacturing companies operate in a uniquely challenging environment: tight margins, constant firefighting, and limited staffing. Yet in most shops, the biggest threats aren’t the obvious ones like machine downtime or supply chain volatility; they’re the hidden, slow-burning inefficiencies buried inside everyday workflows.

Research from organizations such as Deloitte and McKinsey shows that manual processes, including quoting, documentation, and data handling, can drain 20-40 hours of productive time per week and increase error rates by up to 20%.

Below are five common inefficiencies that quietly drain profitability, along with how to recognize them in your operation.

1. Slow Manual Proposal & Quoting Processes

In many small shops, creating a proposal still means juggling spreadsheets, emails, and outdated templates. This isn’t just inconvenient; it’s a competitive disadvantage.

- Sales and engineering lose dozens of hours each week chasing data across systems

- Proposals often take days to complete

- Pricing becomes inconsistent, and engineers get pulled from production

With AI-driven quoting automation, manufacturers can reduce turnaround time by up to 70%, freeing teams to focus on delivering value rather than paperwork.

2. Hidden Administrative Overload

Your team may be working hard, but on the wrong tasks. Manual admin work, like data entry, searching for files, or updating spreadsheets, quietly eats into output.

- Staff spend more time managing files than machines

- Data must be re-entered across CRM, ERP, and accounting systems

- Information lives in too many places, slowing everyone down

AI and workflow automation can complete these tasks in minutes rather than hours, allowing teams to focus on production, customers, and growth.

3. Error-Prone Data Handling

In small manufacturing, data often lives everywhere from ERP and email to handwritten notes. Manual handling not only slows performance but also introduces costly errors in quoting and estimating.

- Frequent rework or mismatched numbers

- Customers questioning accuracy

- Reliance on a few “key people” who know where everything is

Centralized data automation and AI-powered assistants improve accuracy to 99%+ and make critical information accessible to everyone.

4. Fragmented Technology & Systems That Don’t Talk

Over the years of growth, many manufacturers accumulate disconnected tools that don’t communicate. These “islands of information” create bottlenecks and slow workflows.

- Double entry between ERP, CRM, and spreadsheets

- Limited visibility into real-time job status

- Difficulty locating key pricing or scheduling data

An integrated AI layer can connect these systems, creating a unified source of truth that accelerates decisions and cuts wasted motion across departments.

5. Slow Decisions from Outdated or Incomplete Information

Without clear, up-to-date visibility into machine performance, materials, or job profitability, leaders are left guessing. This slows reaction time and increases firefighting.

- Decisions require meetings, calls, or status checks

- No live dashboards or performance summaries

- Frequent last-minute surprises

AI dashboards and predictive models help managers make fast, data-based decisions, sometimes cutting cycle times by 70% or more.

How to Identify Inefficiencies in Your Operation

- Measure quote turnaround time; anything over 48 hours signals friction.

- Counting systems per task at more than 2-3 often indicates fragmentation.

- Track rework and repeated corrections; they indicate data or communication issues.

- Ask your team where they lose time; their answers reveal silent drains.

- Watch for delayed decisions; that’s a sign of missing visibility.